The International Organization for Standardization (ISO) develops international management system standards to ensure that products and services are safe, reliable, and of high quality. These standards help organizations reduce costs, minimize waste and errors, and access new markets. truMaint is a maintenance management system designed to help organizations modernize their maintenance processes and meet ISO standards.

ISO 9000 standards provide organizations with guidance and tools to ensure that their products and services consistently meet customer requirements and that quality is continually improved. Recent revisions to ISO standards necessitate the implementation of computerized maintenance management systems (CMMS) over traditional manual methods. truMaint facilitates this transition by offering a comprehensive maintenance management system that aligns with ISO standards.

The core philosophy of ISO certification involves documenting standard operating procedures, adhering to them, and demonstrating compliance. While implementing truMaint does not automatically guarantee ISO accreditation, utilizing a full-featured maintenance management system like truMaint can significantly aid in the certification process by providing precise equipment maintenance records for auditors.

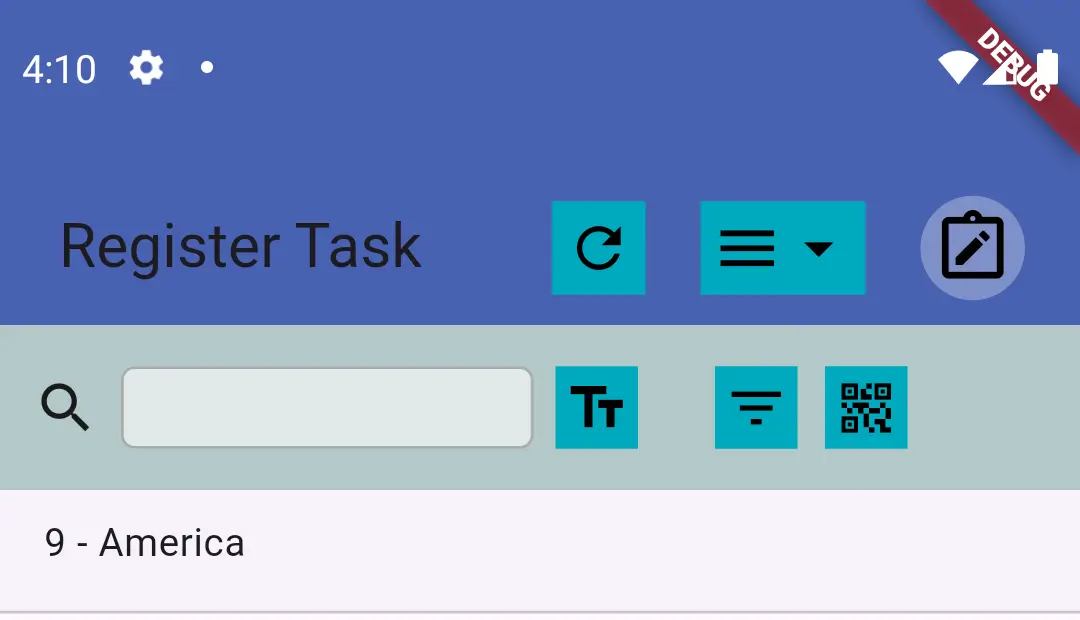

Managing ISO standards for maintenance-related functions can be efficiently accomplished with truMaint. The platform centralizes data, preventing access to outdated information, and allows users to create and edit standard operating procedures with real-time on-screen viewing.

ISO standards require the identification of equipment that directly impacts product quality. truMaint enables users to classify equipment as ISO-critical or non-ISO-critical and identify employees with the necessary skills to maintain ISO-critical equipment. Additionally, procedures can be tagged as ISO or non-ISO related, facilitating easy sorting and retrieval during audits.

Safety procedures, outlining the steps required to perform tasks safely and correctly, form the basis of many ISO equipment maintenance protocols. truMaint allows attachment of safety procedures to preventive maintenance routines, equipment records, and work orders. The platform also includes a comprehensive reporting system capable of generating various reports to demonstrate compliance with ISO standards.

A critical role of maintenance management systems is providing users with the ability to monitor and manage preventive maintenance activities. Effective maintenance directly influences profitability. Features in truMaint that support preventive maintenance include monitoring equipment criticality, equipment data entry, and tracking spare parts inventory. The spare parts inventory management feature ensures that essential inventory is available when equipment failures occur.

Preparing for ISO certification streamlines maintenance management processes and enhances overall efficiency. truMaint can be utilized to track and set due dates for preventive maintenance tasks, generate work orders, and assign them to appropriate technicians based on their skills. Implementing truMaint enhances maintenance department productivity by increasing equipment uptime, reducing unforeseen repairs, and enabling more balanced distribution of preventive maintenance tasks.

truMaint is a versatile maintenance management software solution suitable for various industries, including manufacturing, facilities, and fleet management. The software can be tailored to meet the specific requirements of virtually any company. By utilizing truMaint’s preventive maintenance software, organizations can achieve reduced equipment downtime and improved efficiency, productivity, and profitability.